Case Study: Butler Chemicals, Inc. Wows Customers with the EvoClean Dispenser from Hydro Systems

Challenge

Butler Chemicals, Inc. is a warewash and laundry sales and service company with operations throughout California, Arizona & Nevada. The company specializes in establishing convenient, economical programs that allow foodservice, laundry and housekeeping customers to effectively monitor chemical expenditures. Butler also offers as-needed emergency service and performs monthly preventative maintenance inspections. For laundry customers, these inspections review the laundry process, water quality and temperatures, dryers and dispensing equipment.

In the past, Butler has installed laundry dispensers that rely on squeeze tubes to deliver chemicals to washers. However, these squeeze tubes need replacing every 3-6 months, as over time they result in inconsistent chemical delivery. This can greatly impact the cleanliness of laundered items as well as productivity, sustainability and costs for the laundry operation.

Traditional squeeze tube systems are also visually unappealing and take up a lot of space within a laundry facility. This is because the unit that pumps the chemical and the flush manifold that transfers the laundry products to the washer are separate, and there are many lines running to washers, resulting in a tangled web of equipment in a confined area.

“One of our main challenges has been the lack of visual appeal associated with wall-mounted dispensing units,” said Noel Johnson, Senior Sales Manager, Butler Chemicals, Inc. “Laundry facilities should look their best. Yet with dispensers that use squeeze tubes, you can see the age and dirt in the lines and the equipment can easily become sticky and difficult to clean.”

Solution

In 2018, Butler Chemicals began installing the EvoClean dispenser from Hydro Systems Company at several customer sites. Hydro is a world leader in delivering chemical dispensing and dosing solutions including equipment, software and services.

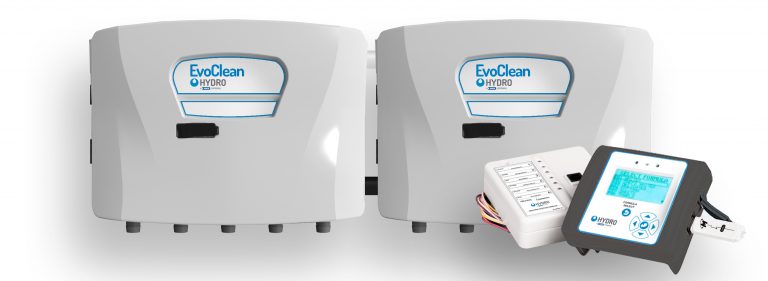

EvoClean is the world’s first venturi-based, water-powered laundry dispenser. It includes an integrated flush manifold and is available in 4-, 6- and 8-product configurations with either low or high chemical flow rate to accommodate all washer sizes used in on-premise laundry operations.

“When Hydro Systems introduced me to the EvoClean dispenser, I realized this was the answer to the space and cleanliness issues that customers face with traditional dispensers,” added Johnson. “Plus, the venturi system eliminates service and repair calls because it consistently delivers the precise amount of chemical to washers.”

Results

Butler Chemicals realizes the following benefits by recommending and installing the EvoClean dispenser at its customers’ sites:

• Consistent chemical delivery. The EvoClean dispenser doses product quickly and also ensures stable, consistent delivery of the chemical to avoid variations that can negatively impact wash cycles.

• Cost savings. Over time, squeeze tubes fail to deliver chemicals perfectly and have to be replaced. Frequent replacement drives up maintenance costs and inconsistent chemical delivery can also drive up laundry costs when cycles have to be rerun. Hydro estimates that on average, operators will save $160/dispenser/year with the EvoClean

• Greater customer satisfaction and peace of mind. Many of Butler’s customers are nursing facilities that must ensure sanitizer and bleach are properly delivered to washers. Often, squeeze tubes have bleach in the line but only pump 20-50 percent of it into the washer. With EvoClean, customers don’t have to worry about chemical compatibility issues associated with some traditional dispensers. Customers avoid emergency calls and can rest assured that linen emerges clean and safe for nursing home occupants.

• Enhanced productivity. EvoClean weighs anywhere from 40-80 percent less than competitive dispensers, making it much easier to install. It also relies on fewer lines, which further reduces installation time. And because EvoClean doesn’t use squeeze tubes, Butler no longer has to replace these components every 3-6 months. In facilities with three to six units on a wall, this process, along with calibrations, used to take a half hour to an hour per customer site.

• Competitive advantage. Butler wants to provide dispensing solutions that are more visually appealing than competitor offerings. EvoClean is state of the art, space saving and easy to service. Because it has fewer lines and a sleeker design, it’s also easier to wipe down and keep clean, helping customers’ laundry facilities look their best.

“I occasionally have prospects and customers that want to see dispenser set-ups at existing customer sites before they agree to an installation. With traditional dispensers, I would have to make sure the units were adequately cleaned and organized before a walk-through,” added Johnson. “With EvoClean, I’m always confident in showing it off. Customers are really amazed by the sleekness and compactness of this venturi dispenser.”

Customer Service and Technical Support

Call 1-800-543-7184 Monday-Friday 8am - 5pm EST