AquaBlend Xtreme

Water-Driven Pump w/ advanced chemical resistance, dilution range (500:1 to 20:1), up to 11 GPM

The AquaBlend Xtreme is a water-driven pump that is resistant to a wide variety of different chemistries that are commonly found in animal health and horticulture applications. Featuring adjustable lower ends, Tool-free maintenance is provided. When you need a pump that can last over 60 million cycles, AquaBlend Xtreme is the answer.

![]()

Lasts up to 60 Million Cycles Before Maintainance

![]()

Toolfree Maintenance Reduces Repair Time by 50%

![]()

Adjustable Lower Ends Allow for Multiple Chemistries to Be Used With One Unit Reducing Total Cost of Ownership

AquaBlend Xtreme Resources

Everything you need all in one place

Longer lasting life

Not only is the AquaBlend Xtreme water-driven pump specifically engineered to accurately inject chemistry into water, it lasts up to 60 million cycles before maintenance is required. The pump's advanced chemical resistance allows the pump to last longer in applications where aggressive chemicals are present.

Tool-free maintenance is a standard feature

AquaBlend Xtreme can be repaired without the need for tools. This water-driven pump can be repaired up to 50% less time compared to other water-driven pumps.

The same pump can be used with multiple lower ends

The ability to use the same pump with different lower ends allows the user to switch between different dilution ratios without having to buy a new pump.

| AquaBlend Model | Part #NPT/BSP | Flow Rate | Injection Rate | Operating Pressure |

| 0.2 - 2% | HYD117947XT HYD117957XT | 0.04 - 11 GPM 10 - 2500 L/hr | 1:500 - 1:50 0.2 - 2% | 5 - 90 psi 0.34 - 6.2 bar |

| 0.8 - 5% | HYD117948XT HYD117958XT | 0.04 - 11 GPM 10 - 2500 L/hr | 1:128 - 1:20 0.8 - 5% | 5 - 90 psi 0.4 - 6.2 bar |

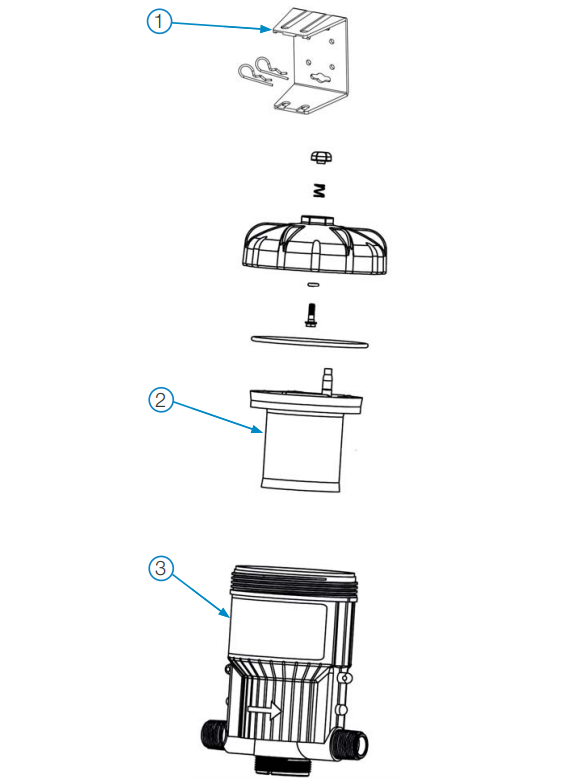

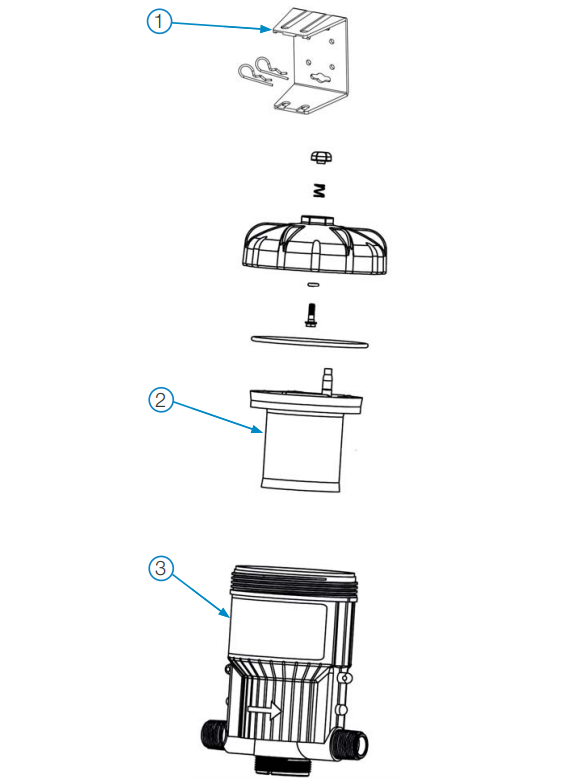

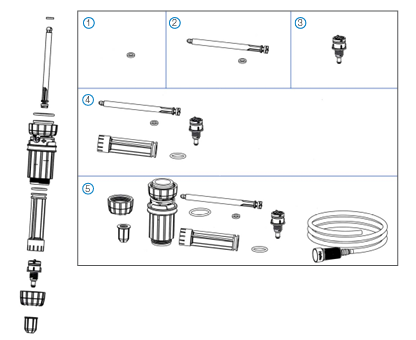

| Key | Part No | Description |

| 1 | HYD011732 | Kit M - Mounting bracket kit |

| 2 | HYD017200XT | Kit H - Motor piston replacement |

| 3 | HYD102601NPT HYD102601BSP | Body, NPT, PVDF, AquaBlend Xtreme Body, BSP, PVDF, AquaBlend Xtreme |

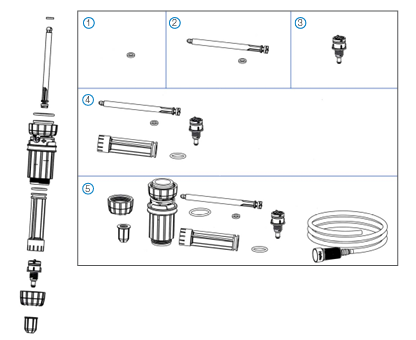

| Key | Part No | Description |

| 1 | HYD017210XT | Kit A: Dosage gasket kit |

| 2 | HYD017211XT | Kit B: Wear kit |

| 3 | HYD017213XT | Kit D: Check valve kit |

| 4 | HYD017214XT | Kit E: Wear parts maintenance kit |

| 5 | HYD017216XT | Kit G: Complete lower end kit |

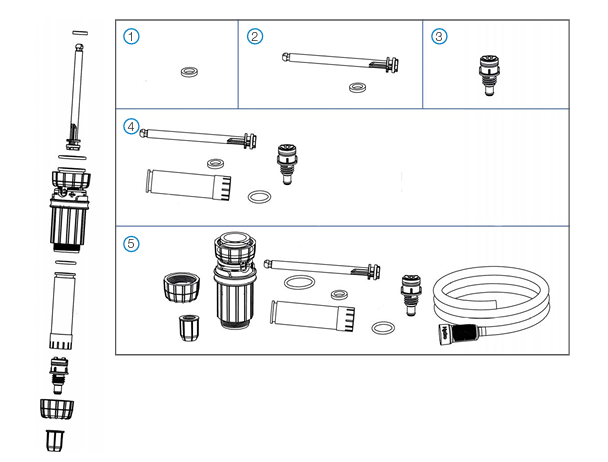

| Key | Part No | Description |

| 1 | HYD017220XT | Kit A: Dosage gasket kit |

| 2 | HYD017221XT | Kit B: Wear kit |

| 3 | HYD017223XT | Kit D: Check valve kit |

| 4 | HYD017224XT | Kit E: Wear parts maintenance kit |

| 5 | HYD17226XT | Kit G: Complete lower end kit |

No files found.

Longer lasting life

Not only is the AquaBlend Xtreme water-driven pump specifically engineered to accurately inject chemistry into water, it lasts up to 60 million cycles before maintenance is required. The pump's advanced chemical resistance allows the pump to last longer in applications where aggressive chemicals are present.

Tool-free maintenance is a standard feature

AquaBlend Xtreme can be repaired without the need for tools. This water-driven pump can be repaired up to 50% less time compared to other water-driven pumps.

The same pump can be used with multiple lower ends

The ability to use the same pump with different lower ends allows the user to switch between different dilution ratios without having to buy a new pump.

| AquaBlend Model | Part #NPT/BSP | Flow Rate | Injection Rate | Operating Pressure |

| 0.2 - 2% | HYD117947XT HYD117957XT | 0.04 - 11 GPM 10 - 2500 L/hr | 1:500 - 1:50 0.2 - 2% | 5 - 90 psi 0.34 - 6.2 bar |

| 0.8 - 5% | HYD117948XT HYD117958XT | 0.04 - 11 GPM 10 - 2500 L/hr | 1:128 - 1:20 0.8 - 5% | 5 - 90 psi 0.4 - 6.2 bar |

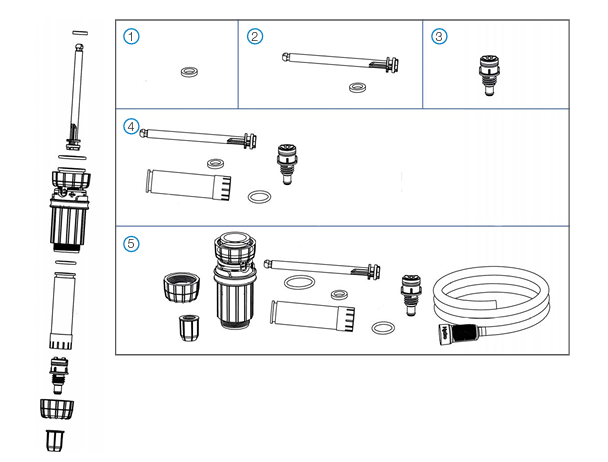

| Key | Part No | Description |

| 1 | HYD011732 | Kit M - Mounting bracket kit |

| 2 | HYD017200XT | Kit H - Motor piston replacement |

| 3 | HYD102601NPT HYD102601BSP | Body, NPT, PVDF, AquaBlend Xtreme Body, BSP, PVDF, AquaBlend Xtreme |

| Key | Part No | Description |

| 1 | HYD017210XT | Kit A: Dosage gasket kit |

| 2 | HYD017211XT | Kit B: Wear kit |

| 3 | HYD017213XT | Kit D: Check valve kit |

| 4 | HYD017214XT | Kit E: Wear parts maintenance kit |

| 5 | HYD017216XT | Kit G: Complete lower end kit |

| Key | Part No | Description |

| 1 | HYD017220XT | Kit A: Dosage gasket kit |

| 2 | HYD017221XT | Kit B: Wear kit |

| 3 | HYD017223XT | Kit D: Check valve kit |

| 4 | HYD017224XT | Kit E: Wear parts maintenance kit |

| 5 | HYD17226XT | Kit G: Complete lower end kit |

No files found.

Ready to get started?

Our experts are here to help. Tell us more about what you need

so we can connect you to the right Hydro experts.

Common Questions

Have a different question? Reach Out

Acetic acid, chlorine (500 ppm or less), and hydrogen peroxide to name just a few. Please check the data sheet for AquaBlend Xtreme for additional chemistries.

Adjustable lower ends are available. Fixed lower ends are not available.

90 psi or 6.2 bar.

100 degrees F. or 38 degrees C.

11 GPM or 2500 l/hr.