Solution Center

Everything you need

all in one place

Hydro Product Resources

Calculators

Please choose a product below for solutions to many common conditions that are often addressed by our Technical Service department.

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming In Discharge

Cause: Air leak in pick-up tube

Solution: Put clamp on tube or replace tube if brittle

No Concentrate Draw

Cause: Concentrate container empty

Solution: Replace with full container

No Concentrate Draw

Cause: Concentrate container empty

Solution: Replace with full container

Excess Foaming In Discharge

Cause: Air leak in pick-up tube

Solution: Put clamp on tube or replace tube if brittle

Dead or No Display

Insure that controller is connected to pump module via J1 cable

Insure that power is connected to pump module

Check to see if the pump module circuit breaker is tripped

Load Count Errors

Quite a number of perceived load count errors may occur in the normal day-to-day operations of a laundry. A load is counted (to the current formula number) each time the highest pump number with a nonzero amount runs. In Relay mode a load is counted each time pump 1 is run.

Load Counts High

Check washer trigger signal for count pump running more than once each load

Load Counts Low

Check washer trigger signals

Check that machine operator may be short cycling the washer

Pumps Don’t Prime

Confirm pump motor harness is connected to PI PCB in pumpstand

Follow pumpstand manual troubleshooting procedures for PI PCB defect

Pumps Don’t Run

When pumps don’t run it is important to differentiate between running on prime and running from a machine trigger. Pumps only run formula amounts from a machine trigger when pumps are calibrated.

When only certain pump positions are defective, check Pump Interface (PI) printed circuit board (PCB) and J1 cable connections.

Only one pump may run at a time in flush mode. Multiple pumps triggered at the same time will run in queue.

No Pumps On Trigger, Prime OK

Are pumps calibrated?

Is a delay time programmed or is pump in cue?

Is there a trigger signal? Confirm by viewing lights on Machine Interface and measuring signal with a volt meter.

Follow pump module manual troubleshooting procedures for MI defect

Test run pump amounts as described in step 5.4.2 or Program Mode

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

Discharge From Backflow Preventer Vent

Cause: Backflow preventer check valve dirty or defective Water hammer condition in supply system (cause of “splitting”) Negative pressure in supply line causing reverse flow

Solution: Clean or replace backflow preventer (Kit #105) Install water hammer shock arresters or water pressure reducing valves

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Leaks At Plastic And Copper Junctions

Cause: Compression nut loose

Solution: Tighten nut 1/2 turn

Leaks At Plastic Tube

Cause: Compression nut loose

Solution: Tighten nut 1/2 turn

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Cause: Clogged foot strainer

Solution: Clean or replace

Cause: Low water pressure and/or volume

Solution: Replace with full container

Cause: Check valve not screwed into eductor firmly

Solution: Tighten, but DO NOT OVERTIGHTEN!

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 85 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Flow Won’t Shut Off

Cause: Ball valve defective

Solution: Replace

Weak Foaming Action

Cause: Clogged water inlet strainer

Solution: Clean or replace

Cause: Water pressure too low

Solution: Minimum 25 PSI required

Cause: Water temperature too high

Solution: Use lower temp water source (Concentrate flow decreases above 140 degrees F water)

Weak Spraying Action

Cause: Clogged water inlet strainer

Solution: Clean or replace

Cause: Water pressure too low

Solution: Minimum 25 PSI required

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

Discharge From Backflow Preventer Vent

Cause: Backflow preventer check valve dirty or defective

Solution: Clean or replace backflow preventer (Kit #105)

Cause: Water hammer condition in supply system (cause of “splitting”)

Solution: Install water hammer shock arresters or water pressure reducing valves

Cause: Negative pressure in supply line causing reverse flow

Solution: This is the proper operation of this component. Cause of negative pressure must be corrected.

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Leaks At Plastic And Copper Junctions

Cause: Compression nut loose

Solution: Tighten nut 1/2 turn

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Flow Won’t Shut Off

Cause: Ball valve defective

Solution: Replace

No Discharge

Cause: No water

Solution: Open water supply

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 85 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Cause: Clogged foot strainer

Solution: Clean or replace

Cause: Low water pressure and/or volume

Solution: Replace with full container

Cause: Check valve not screwed into eductor firmly

Solution: Tighten, but DO NOT OVERTIGHTEN!

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Leaks At Plastic And Copper Junctions

Cause: Compression nut loose

Solution: Tighten nut 1/2 turn

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Cause: Clogged foot strainer

Solution: Clean or replace

Cause: Low water pressure and/or volume

Solution: Clean or replace

Cause: Check valve not screwed into eductor firmly

Solution: Tighten, but DO NOT OVERTIGHTEN!

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Weak Foaming Action

Cause: Clogged water inlet strainer

Solution: Clean or replace

Cause: Water pressure too low

Solution: Minimum 25 PSI required

Cause: Water temperature too high

Solution: Use lower temp water source (Concentrate flow decreases above 140 degrees F water)

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

Excess Foaming In Discharge

Cause: Air leak in pick-up tube

Solution: Put clamp on tube or replace tube if brittle

No Concentrate Draw

Cause: Concentrate container empty

Solution: Replace with full container

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Cause: Clogged foot strainer

Solution: Clean or replace

Cause: Low water pressure and/or volume

Solution: Replace with full container

Cause: Check valve not screwed into eductor firmly

Solution: Tighten, but DO NOT OVERTIGHTEN!

*In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Weak Spraying Action

Cause: Clogged water inlet strainer

Solution: Clean or replace

Cause: Water pressure too low

Solution: Minimum 25 PSI required

Excess Concentrate Draw

Cause: Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

Excess Concentrate Draw

Cause: Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on the eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing).

Dead or No Display

Confirm main power connection voltage with a volt meter. Check fuse if optional fuse kit is installed. Substitute transformer followed by the printed circuit board to determine fault.

Excess Detergent Consumption

7.4.1 Probe Mode

Check probe for scaling and measure wash solution via titration kit or by other means. If detergent us at proper concentration, troubleshoot the dish machine for clogged drains, excessive fresh water feedback, etc.

7.4.2 Probe-less Mode

Confirm that initial charge is dispensed only one time per initial fill. if you experience multiple initial charge feeds (Automatic/Conveyor mode only) review initial charge wiring connection. All other modes, adjust initial charge and dose adjustments accordingly.

No Detergent Feed

7.3.1 Probe Mode

Temporarily disconnect probe wire with detergent signal on to force detergent feed.

If detergent feeds, check for probe scaling and check detergent setpoint setting.

If detergent does not feed, substitute pump motor (or solenoid coil) followed by the printed circuit board to determine fault.

7.3.2 Probe-less Mode

Confirm that unit is in a detergent feed condition as determined by rinse/initial charge signal inputs and initial charge/dose adjustments.

If detergent does not feed, substitute pump motor (or solenoid coil) followed by the printed circuit board to determine fault.

No Rinse Feed

Rinse feed is locked out under the following conditions:

Probe-less/Door/Automatic Initial Charge modes – Rinse is locked out after Initial Charge begins until the following rack (rinse signal) occurs.

Probe Mode – detergent signal did not occur within 90 seconds prior to rinse signal (Rinse Saver feature).

If not in one of the above conditions and rinse does not feed, substitute pump motor followed by the printed circuit board to determine fault.

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

Unit Is Not Pumping Fluid

If the motor is turning check level of drain treatment supply check for air leaks in the supply tubing connection to pump tube stems check for clogs in inlet and outlet tubes insure pump tube is not at all twisted check pump tube. As it wears out, the amount of fluid pumped decreases. Change tube.

If the motor is not turning ensure programmer is functioning: Try to run pump manually (see page 3 of the instruction manual) check program: Be sure both switches are in center position for programmed dispensing check to insure wires from the electronic control to the motor are secure ensure that wire from batteries to electronic control is secure check battery condition. Try new batteries. BE SURE TIMER IS OFF before changing the batteries remove the pump to see if pump is binding the motor (run motor manually — see page 3 of the instruction manual)

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Cause: Clogged foot strainer

Solution: Clean or replace

Cause: Low water pressure and/or volume

Solution: Replace with full container

Cause: Check valve not screwed into eductor firmly

Solution: Tighten, but DO NOT OVERTIGHTEN!

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 85 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Flow Won’t Shut Off

Cause: Ball valve defective

Solution: Replace

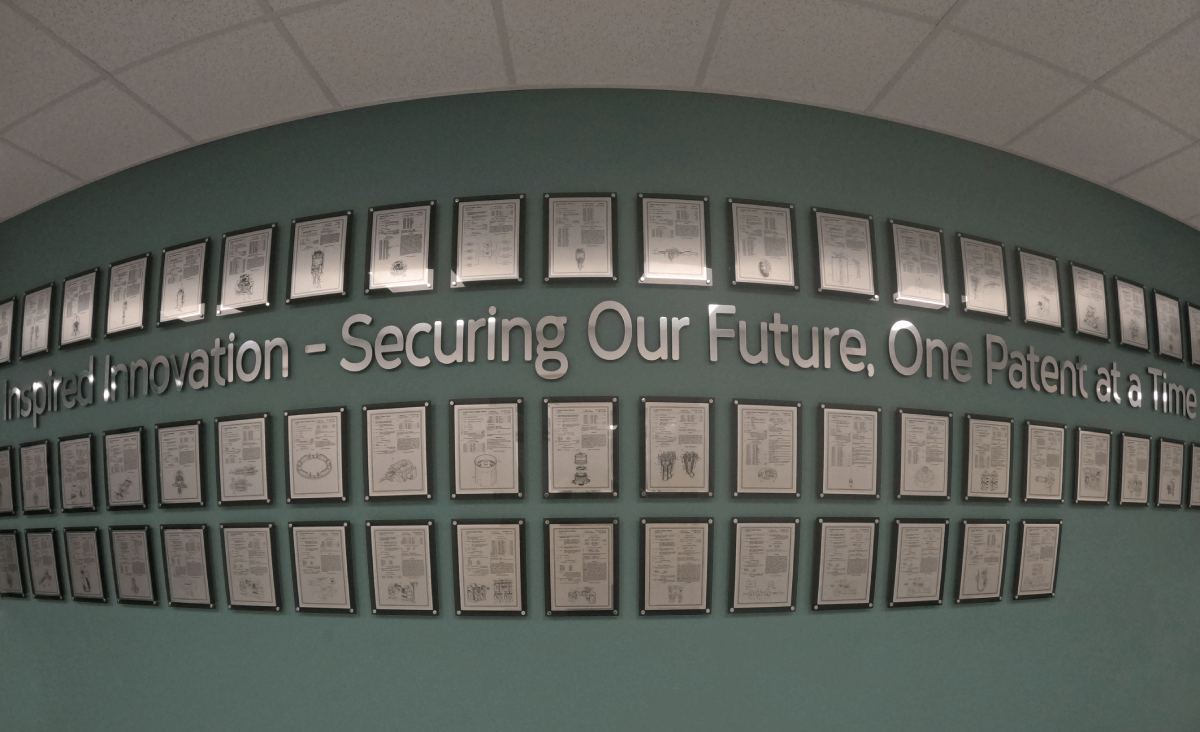

| TITLE | PATENT NUMBER | ISSUE/PUBLICATION DATE (mm/dd/yyyy) | COUNTRY |

| Remotely Activated Dispenser | 6299035 | 10/09/2001 | USA |

| Backflow Preventing Eductor | 6634376 | 02/20/2003 | USA |

| Multiple Flow Rate Eductive Dispenser | 6619318 | 03/27/2003 | USA |

| Multiple Chemical Product Eductive Dispenser | 6655401 | 03/27/2003 | USA |

| Replaceable Seal | 6254366 | 07/03/2003 | USA |

| Leveling Mounting Bracket | 6877641 | 04/29/2004 | USA |

| On/Off Switch for Liquid Additive Injection Pump | 6910405 | 01/13/2005 | USA |

| Cable Sealing Apparatus and Method | 6888067 | 05/03/2005 | USA |

| Liquid Additive Injection Pump With Mixing Chamber and One Way Valve | 7438537 | 09/14/2006 | USA |

| Improved Chemical Dispenser | 7487795 | 11/23/2006 | USA |

| Solution Dispensing System | 8008082 | 11/22/2007 | USA |

| Control for Dispensing System | 8956579 | 11/05/2009 | USA |

| RFID Controlled Chemical Proportioner and Dispenser | 8261780 | 02/04/2010 | USA |

| Dispenser With Inline Pressure Regulator | 8813789 | 02/04/2010 | USA |

| Chemical Dispensing Apparatus and Methods | 8499979 | 12/29/2011 | USA |

| Controller for Water Treatment | 8532829 | 04/19/2012 | USA |

| Probe for Water Treatment | 8926834 | 04/19/2012 | USA |

| Communication Network for Water Treatment | 9014194 | 04/19/2012 | USA |

| Bottle Cartridge | 8844776 | 05/03/2012 | USA |

| Intelligent Network for Chemical Dispensing System | 9447536 | 04/18/2013 | USA |

| Communication Network for Water Treatment | 9800500 | 08/06/2015 | USA |

| Interface Module for Chemical Dispensing | 10110680 | 10/05/2016 | USA |

| Intelligent Network for Chemical Dispensing System (DIV) | 9835148 | 12/01/2016 | USA |

| Wireless Interface Module for Chemical Dispensing Systems | 10003653 | 02/16/2017 | USA |

| Remotely Activated Dispenser | 10478845 | 11/19/2019 | USA |

| Wideband Optical Sensor and Use Thereof in Dispensing Systems | 10591411 | 03/17/2020 | USA |

| Improved Chemical Dispenser | 1904218 | 04/02/2008 | UK |

| Cultivation and Dispensing of Bacteria | 2484887 | 05/02/2012 | UK |

| Intelligent Network for Chemical Dispensing System | 2581486 | 04/17/2013 | UK |

| Fluid Dispenser Having An NFC Tag, and System Incorporating Same | 2568941 | 06/05/2019 | UK |

| Liquid dispensing device | 2560383 | 09/12/2019 | UK |

| Liquid Additive Injection Pump With Mixing Chamber and One Way Valve | 1869321 | 12/26/2007 | Germany |

| Improved Chemical Dispenser | 602006037385.6 | 04/02/2008 | Germany |

| Intelligent Network for Chemical Dispensing System | 2581486 | 04/17/2013 | Germany |

| Liquid Additive Injection Pump With Mixing Chamber and One Way Valve | 1869321 | 12/26/2007 | France |

| Intelligent Network for Chemical Dispensing System | 2581486 | 04/17/2013 | France |

| Liquid Additive Injection Pump With Mixing Chamber and One Way Valve | 2600802 | 09/21/2006 | Canada |

| Improved Chemical Dispenser | 2608983 | 11/23/2006 | Canada |

| Liquid Additive Injection Pump With Mixing Chamber and One Way Valve | 1869321 | 12/26/2007 | Austria |

Thank you for visiting this page dedicated to products we have discontinued. The reference materials found here support products no longer actively marketed by Hydro Systems Company.

If you do not find what you need, or require further assistance, please feel free to contact Hydro Systems toll-free at 1-800-543-7184, our Customer Service team is eager to assist you.

Calculators

Please choose a product below for solutions to many common conditions that are often addressed by our Technical Service department.

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

Water Discharge From Air Vents On Eductor

Cause: Restricted discharge hose

Solution: Be sure discharge tube is not immersed, kinked, or elevated. Be sure there is no liquid in the discharge tube when beginning to operate dispenser

Cause: High water pressure

Solution: Install pressure regulator if flowing water pressure exceeds 60 PSI (flowing)

No Discharge

Cause: No water

Solution: Open water supply

Cause: Magnetic valve not functioning

Solution: Install valve parts kit

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 60 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged foot valve

Solution: Clean or replace

Cause: Metering tip or eductor has scale build-up

Solution: Clean (descale)* or replace

Cause: Low water pressure

Solution: Minimum 20 PSI (with water running) required to operate unit properly

Cause: Discharge tube(s) not in place or flooding ring missing from inner discharge tube

Solution: Push tube firmly onto eductor discharge hose barb; be sure inner discharge tube is installed and has flooding ring

Cause: Concentrate container empty

Solution: Replace with full container

Cause: Inlet hose barb not screwed into eductor tightly

Solution: Tighten, but do not overtighten

Cause: Clogged water inlet strainer

Solution: Disconnect inlet water line and clean strainer

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Failure Of Unit To Turn Off

Cause: Water valve parts dirty or defective

Solution: Clean or replace with valve parts kit

Cause: Magnet does not fully return

Solution: Ensure magnet moves freely

Cause: Push button stuck

Solution: Remove button and clean cabinet/button to remove any dirt lodged in slide recess

Excess Foaming in Discharge

Cause: Air leak in pick-up tube

Solution: Put a clamp on tube or replace tube if brittle

Excess Concentrate Draw

Cause: Metering tip not in place

Solution: Press correct tip firmly into barb on eductor

Cause: Chemical above eductor

Solution: Place concentrate below the eductor

Excess Foaming In Discharge

Cause: Air leak in pick-up tube

Solution: Put clamp on tube or replace tube if brittle

No Concentrate Draw

Cause: Concentrate container empty

Solution: Replace with full container

No Concentrate Draw

Cause: Concentrate container empty

Solution: Replace with full container

Excess Foaming In Discharge

Cause: Air leak in pick-up tube

Solution: Put clamp on tube or replace tube if brittle

Dead or No Display

Insure that controller is connected to pump module via J1 cable

Insure that power is connected to pump module

Check to see if the pump module circuit breaker is tripped

Load Count Errors

Quite a number of perceived load count errors may occur in the normal day-to-day operations of a laundry. A load is counted (to the current formula number) each time the highest pump number with a nonzero amount runs. In Relay mode a load is counted each time pump 1 is run.

Load Counts High

Check washer trigger signal for count pump running more than once each load

Load Counts Low

Check washer trigger signals

Check that machine operator may be short cycling the washer

Pumps Don’t Prime

Confirm pump motor harness is connected to PI PCB in pumpstand

Follow pumpstand manual troubleshooting procedures for PI PCB defect

Pumps Don’t Run

When pumps don’t run it is important to differentiate between running on prime and running from a machine trigger. Pumps only run formula amounts from a machine trigger when pumps are calibrated.

When only certain pump positions are defective, check Pump Interface (PI) printed circuit board (PCB) and J1 cable connections.

Only one pump may run at a time in flush mode. Multiple pumps triggered at the same time will run in queue.

No Pumps On Trigger, Prime OK

Are pumps calibrated?

Is a delay time programmed or is pump in cue?

Is there a trigger signal? Confirm by viewing lights on Machine Interface and measuring signal with a volt meter.

Follow pump module manual troubleshooting procedures for MI defect

Test run pump amounts as described in step 5.4.2 or Program Mode

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

Discharge From Backflow Preventer Vent

Cause: Backflow preventer check valve dirty or defective Water hammer condition in supply system (cause of “splitting”) Negative pressure in supply line causing reverse flow

Solution: Clean or replace backflow preventer (Kit #105) Install water hammer shock arresters or water pressure reducing valves

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Leaks At Plastic And Copper Junctions

Cause: Compression nut loose

Solution: Tighten nut 1/2 turn

Leaks At Plastic Tube

Cause: Compression nut loose

Solution: Tighten nut 1/2 turn

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Cause: Clogged foot strainer

Solution: Clean or replace

Cause: Low water pressure and/or volume

Solution: Replace with full container

Cause: Check valve not screwed into eductor firmly

Solution: Tighten, but DO NOT OVERTIGHTEN!

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Discharge

Cause: No water

Solution: Open water supply

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 85 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Flow Won’t Shut Off

Cause: Ball valve defective

Solution: Replace

Weak Foaming Action

Cause: Clogged water inlet strainer

Solution: Clean or replace

Cause: Water pressure too low

Solution: Minimum 25 PSI required

Cause: Water temperature too high

Solution: Use lower temp water source (Concentrate flow decreases above 140 degrees F water)

Weak Spraying Action

Cause: Clogged water inlet strainer

Solution: Clean or replace

Cause: Water pressure too low

Solution: Minimum 25 PSI required

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

Discharge From Backflow Preventer Vent

Cause: Backflow preventer check valve dirty or defective

Solution: Clean or replace backflow preventer (Kit #105)

Cause: Water hammer condition in supply system (cause of “splitting”)

Solution: Install water hammer shock arresters or water pressure reducing valves

Cause: Negative pressure in supply line causing reverse flow

Solution: This is the proper operation of this component. Cause of negative pressure must be corrected.

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Backflow Into Concentrate

Cause: Eductor check valve inoperable

Solution: Clean or replace check valve

Excess Concentrate Draw

Cause: Metering tip not in place (or wrong metering tip)

Solution: Press correct tip firmly into barb

Leaks At Plastic And Copper Junctions

Cause: Compression nut loose

Solution: Tighten nut 1/2 turn

Low Or No Water Flow

Cause: Inlet screen clogged

Solution: Clean or replace

Cause: Supply source inadequate

Solution: 4 GPM flow necessary to operate unit; move unit or replumb incoming line

Cause: Scaled eductor or fittings

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

Water Flow Won’t Shut Off

Cause: Ball valve defective

Solution: Replace

No Discharge

Cause: No water

Solution: Open water supply

Cause: Excessive water pressure

Solution: Install regulator if water pressure exceeds 85 PSI (flowing)

Cause: Eductor clogged

Solution: Clean* or replace

* In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner. Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit. Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into concentrate.

No Concentrate Draw

Cause: Clogged check valve

Solution: Clean or replace

Cause: Metering tip clogged

Solution: Rinse in hot water or replace: DO NOT REAM CLEAN!

Cause: Eductor clogged

Solution: Clean or replace

Cause: Clogged water inlet

Solution: Clean screen

Cause: Clogged foot strainer

Solution: Clean or replace

Cause: Low water pressure and/or volume

Solution: Replace with full container

Cause: Check valve not screwed into eductor firmly

Solution: Tighten, but DO NOT OVERTIGHTEN!